Fundamental technology for automatic processes: Machine vision systems in mechanical engineering and plant construction

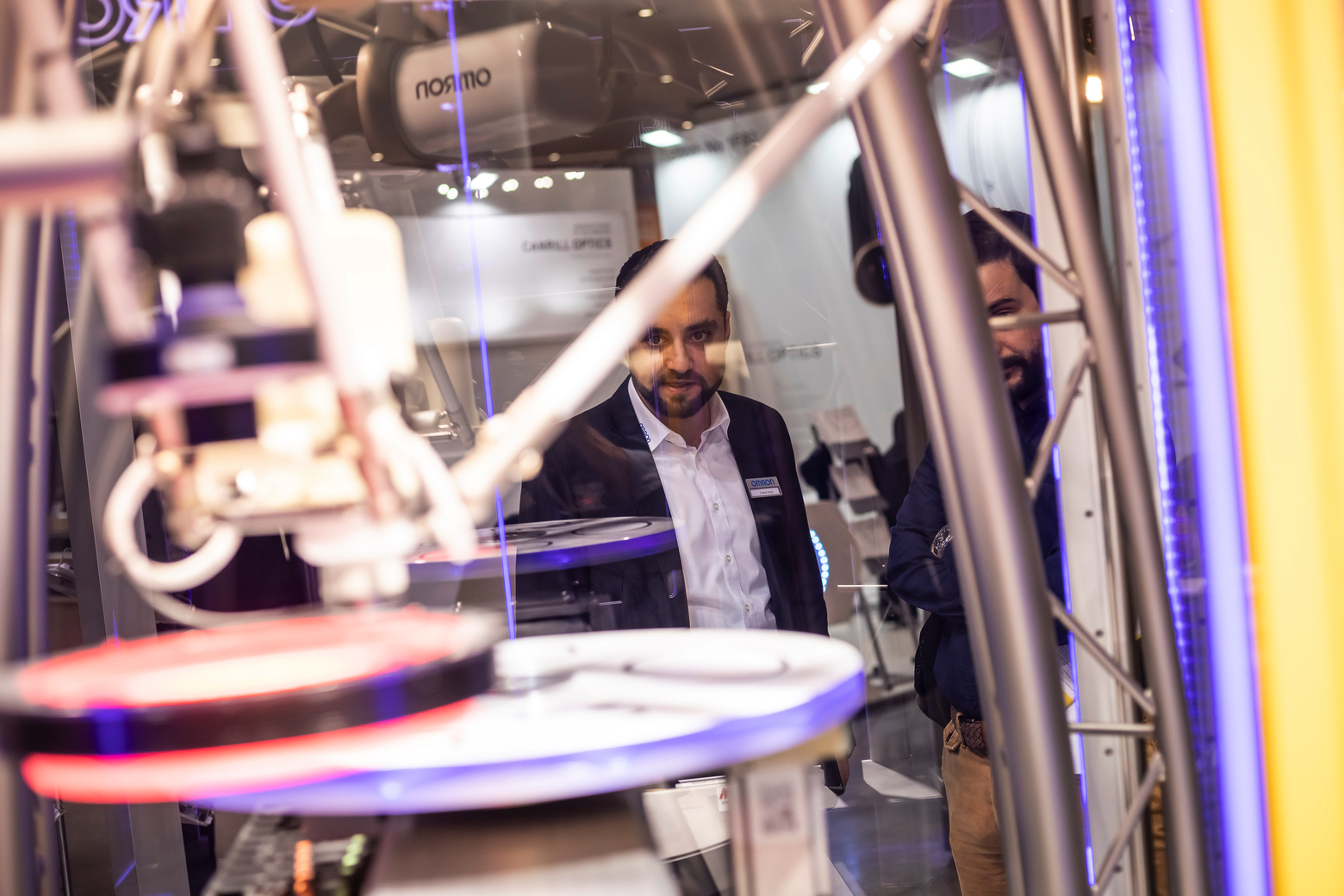

Machine Vision uses imaging sensor systems and computer vision processes to control machines. In production, they are employed in quality assurance, for instance. The systems use various criteria to check products and automatically sort out or stop the production line in case of processing errors.

One of the most important image processing technologies in the area of machine vision are embedded vision systems. They are more compact, cheaper and more robust than classic industrial machine vision systems. They meet the higher requirements for the use in harsh environmental conditions, where properties such as shock and impact resistance or suitability for extended temperature ranges are absolutely essential. Due to the miniaturisation of their electronic components, embedded vision systems can be integrated directly into machines, devices or products.

Today, industrial machine vision is one of the fastest-growing industrial sectors in mechanical engineering and plant construction in Germany. It facilitates the progressive automation of processes, which is becoming increasingly important for low-error, cost-effective and sustainable production. The boom in machine vision is currently attracting investments, as falling prices for the most important components and simultaneous increases in the performance of sensors and processors are also positively impacting cameras and system performance in machine vision.

zurück zur Übersicht