SCHOOLTOOL

![SCHOOLTOOL [Translate to English:]](/moulding-expo/fileadmin/media/besucher/Rahmenprogramm/MEX_Box/mex-23-hochschule-reutlingen-shooltool-header-2.jpg)

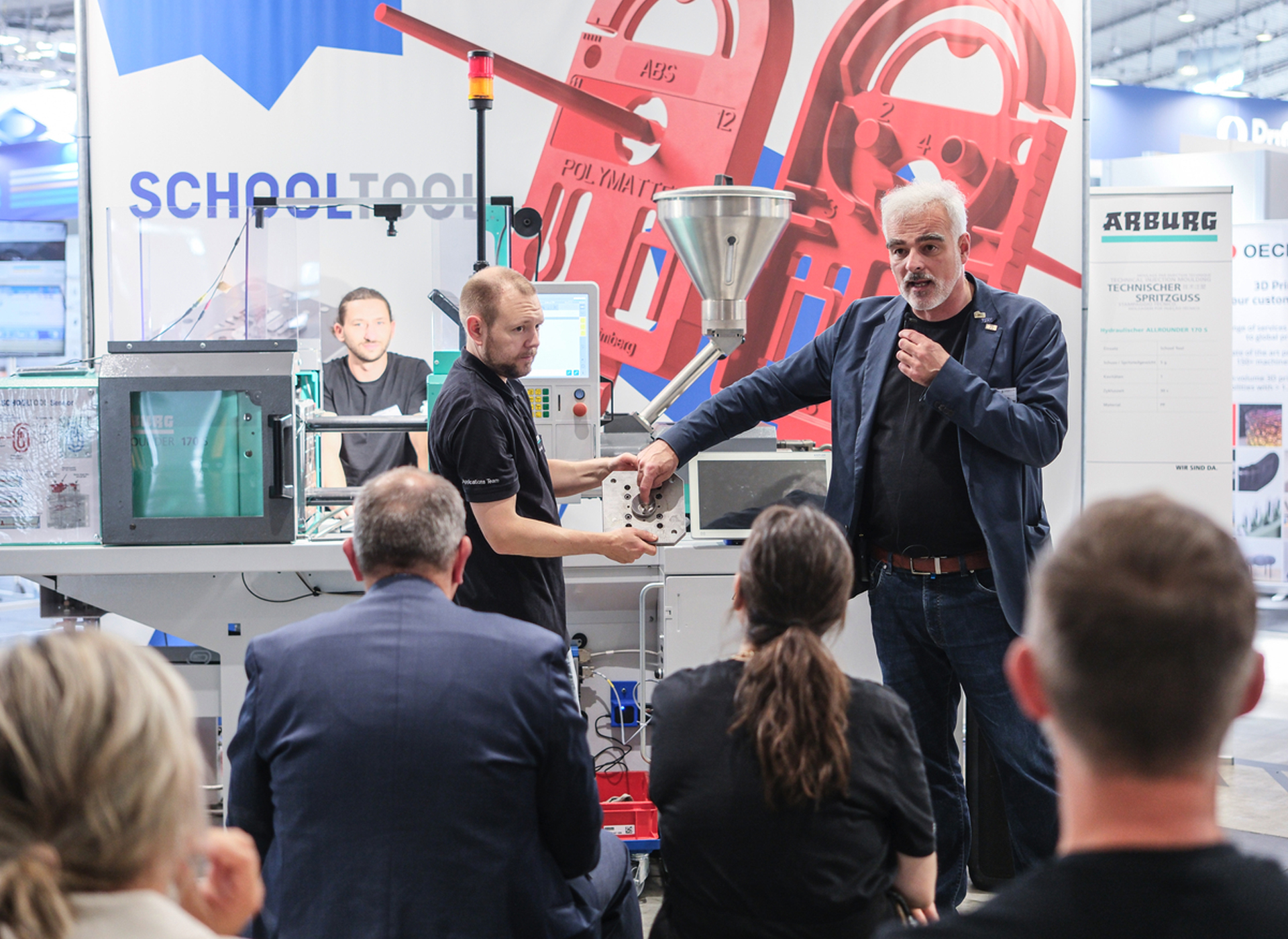

SCHOOLTOOL is a holistic, versatile and conceptually coordinated teaching and learning concept in the field of moulded part and injection moulding tools, moulded part development and injection moulding processes.

The concept combines the fields of craft training with those of academic engineers’ training.

It shows how knowledge is conveyed to students and trainees with fun and motivation through inspiring projects.

SCHOOLTOOL provides an improved understanding of the individual steps in the product development process.

Mouldmaker the game is a card game in which players have to assemble a tool.

The basic structure of different injection mould types are practised and learned as well as the different types of technical representation.

At the stand of Reutlingen University visitors had the chance to secure the official Moudling Expo Give-Away mouldmaker the game!

Only one thing remains to be said: Have fun making tools!