MARPOSS

Measurement, Inspection and Testing Systems

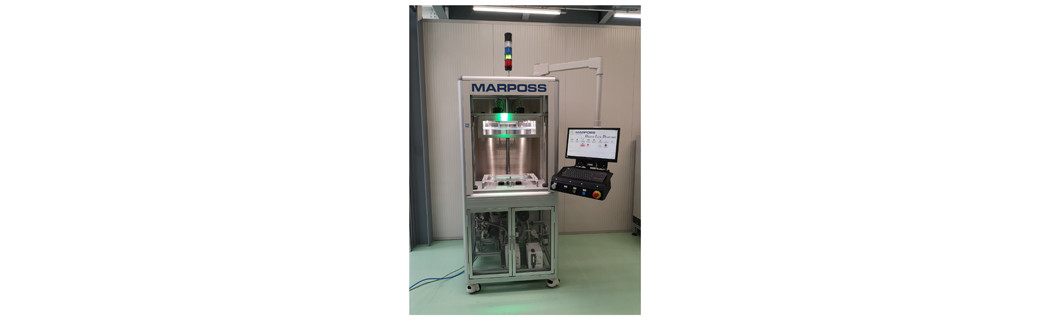

Long-term MARPOSS experience in the process monitoring and in-line control is applied to the manufacturing of H2 industry equipment (fuel cells and electrolysers), with the development of tailored solutions to check the integrity, dimension and functionality of all components, in order to prevent the assembly of defective parts that would negatively affect the final quality of the stack or the total equipment.

On the hy-fcell 2023 trade fair in Stuttgart MARPOSS is focussing on leak testing, dimensional & inspection gauging of bipolar-plates (BPP) and monitoring solutions. Leak testing is a specific test operation in the flow- and bipolar-plate’s production process, since it verifies the tightness of coolant, hydrogen and air circuits of the plates, simulating real operating condition. The MARPOSS dimensional and inspection gauging applications of bipolar-plates are based on multiple confocal sensors. The application aims to measure all relevant dimensional characteristics of a BPP, such as overall dimensions, depth and width of each single channel, thickness.üfen, wie z.B. die Gesamtabmessungen, die Tiefe und Breite jedes einzelnen Kanals und die Dicke.